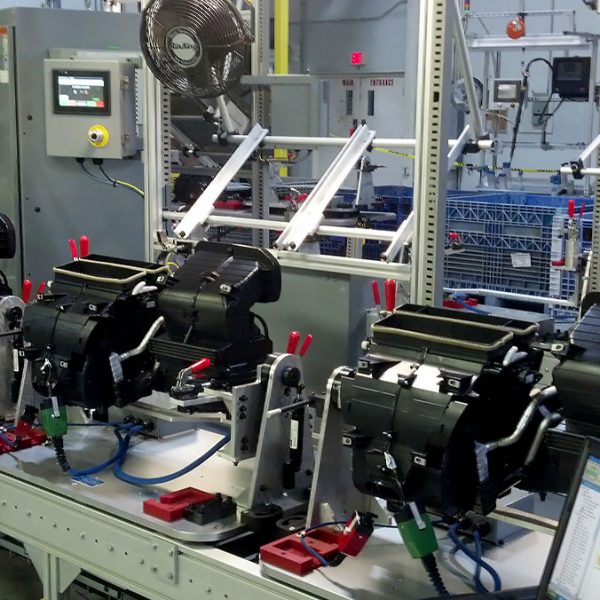

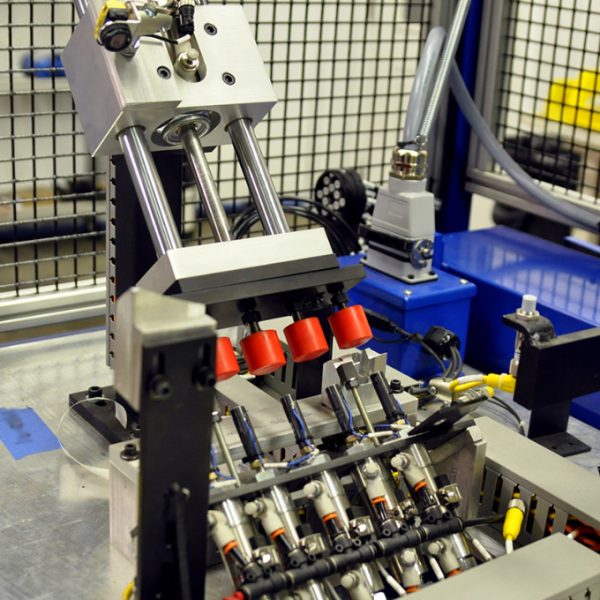

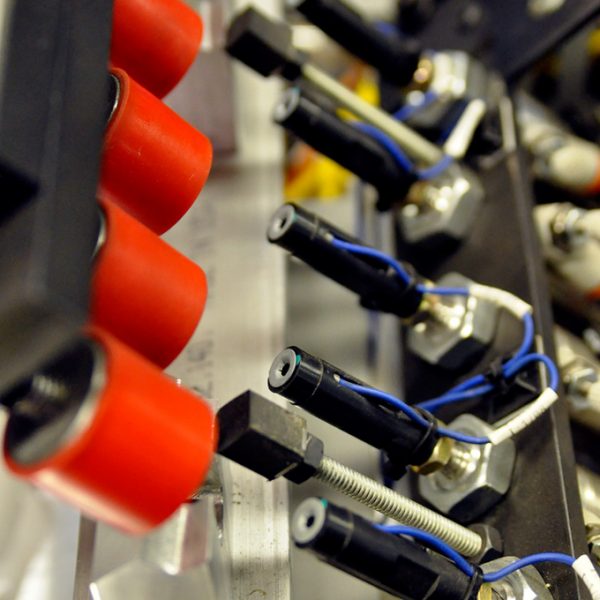

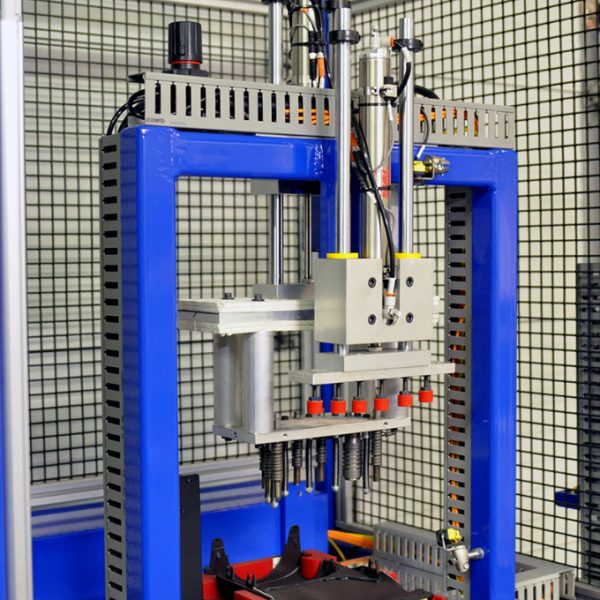

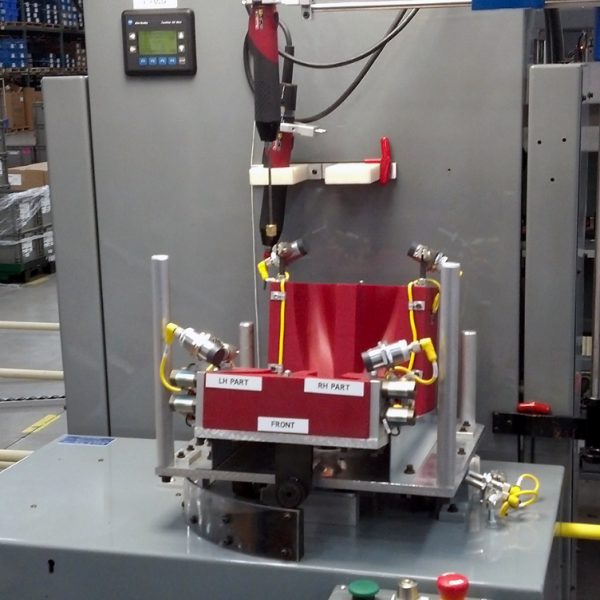

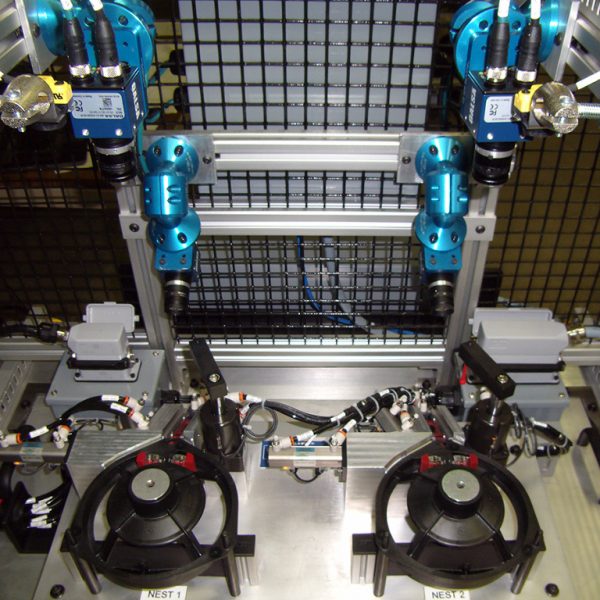

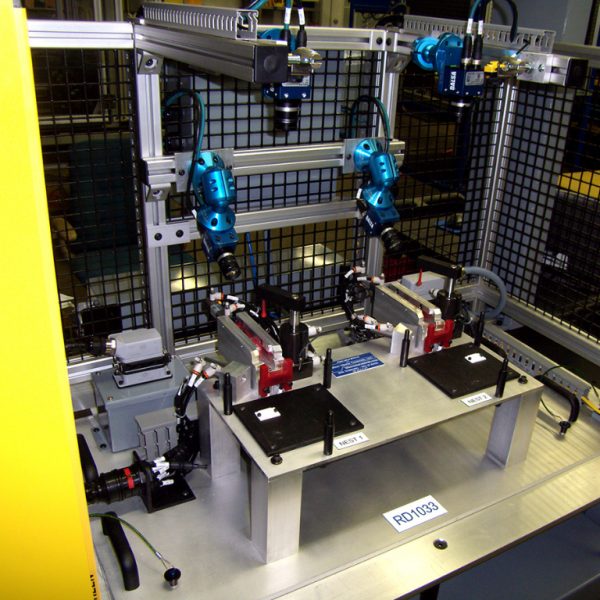

Clip Assembly Equipment:

We excel in fully automated and operator driven clip assembly machines. Our machines accurately install any type of clip: plastic, metal, or combinations with gaskets or rubber. Bowl feed equipment can be included to assemble clips on injection molded parts while the parts are still on the end of arm tool or robot. No human intervention is necessary prior to the completely assembled part being presented for packaging.

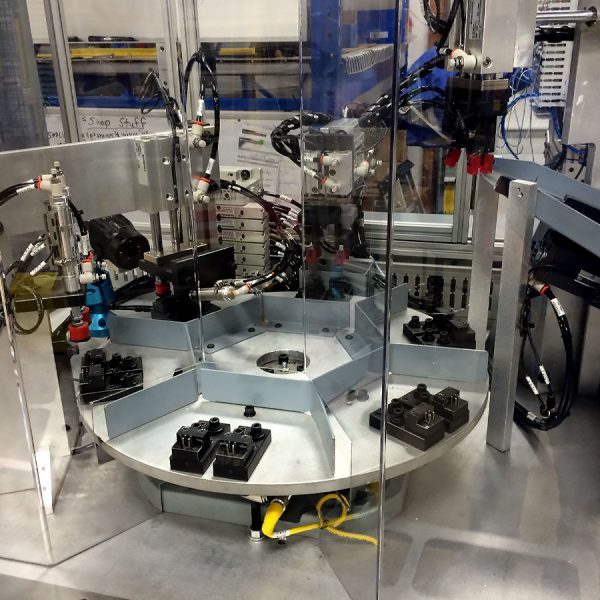

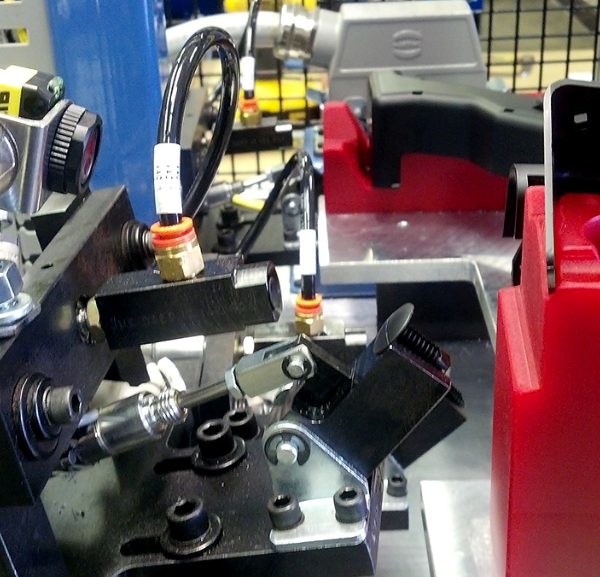

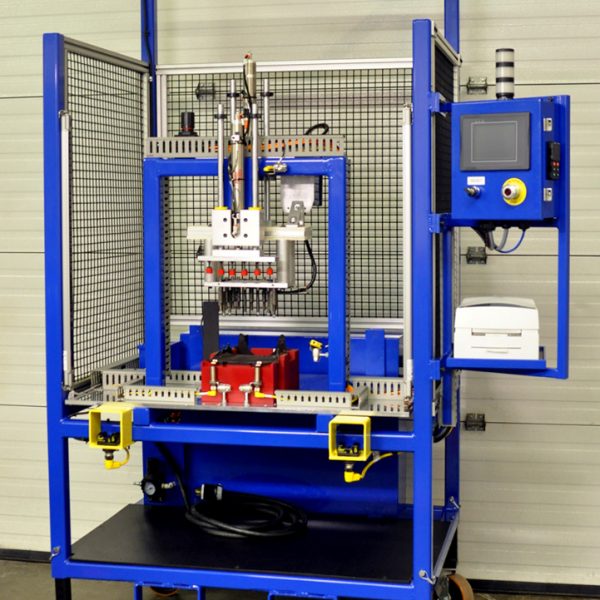

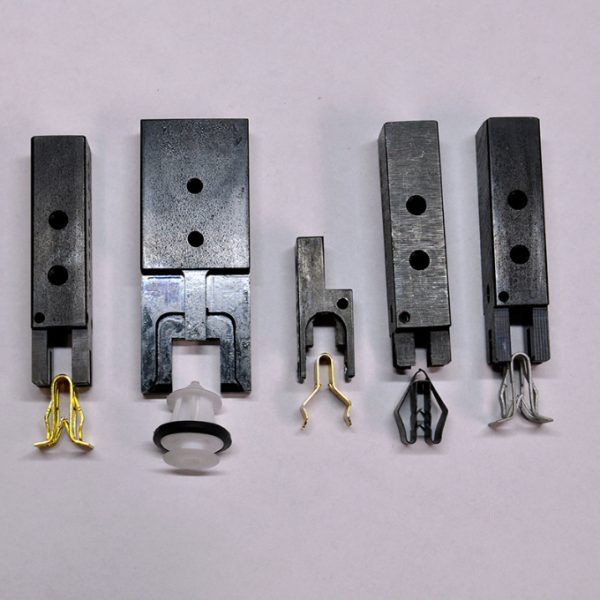

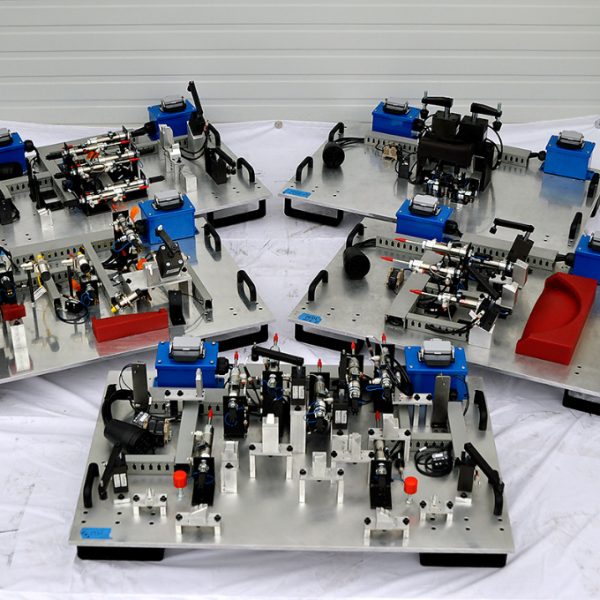

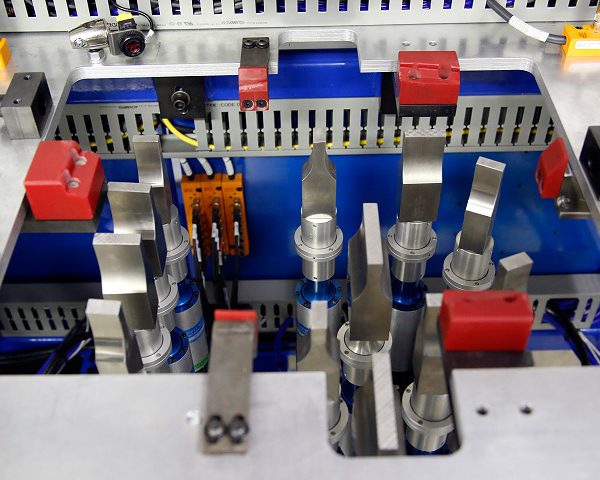

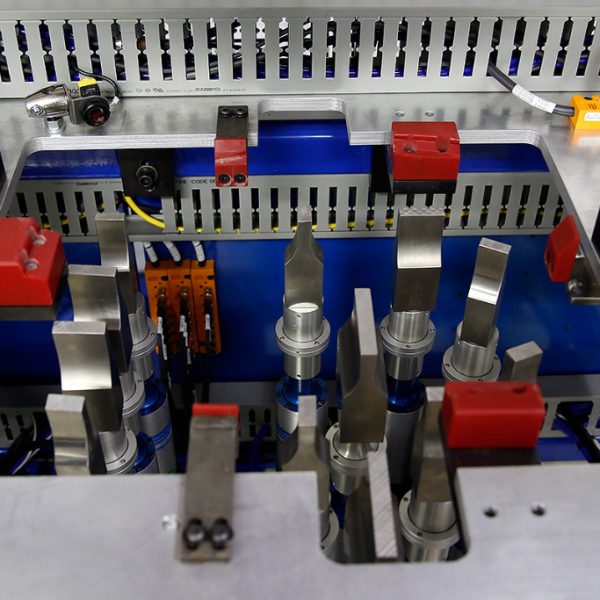

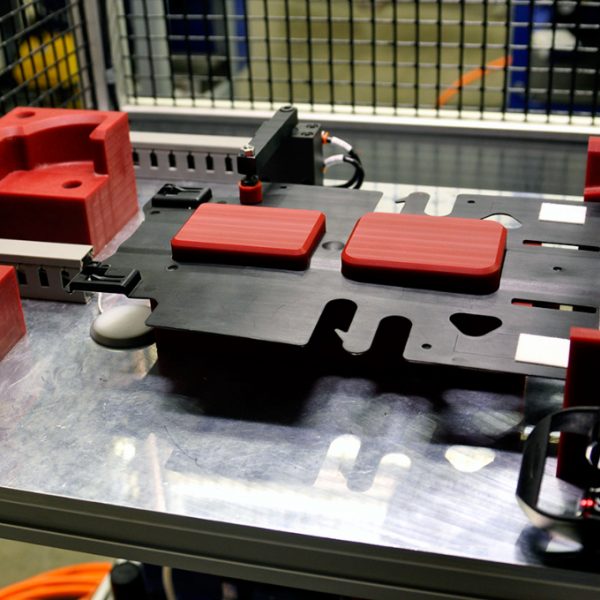

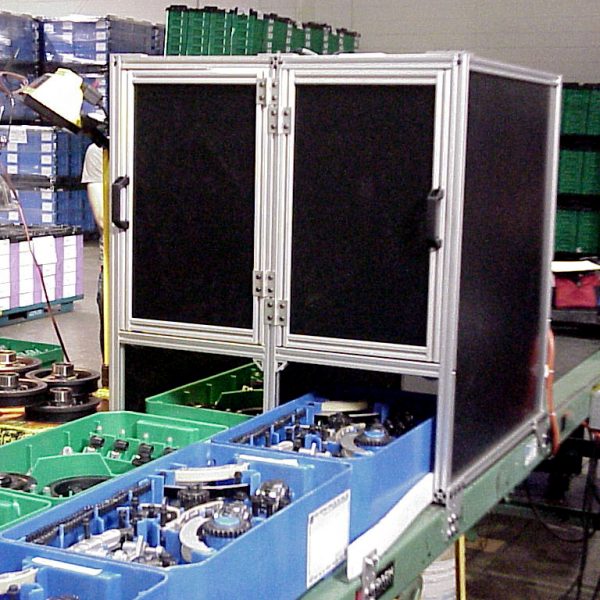

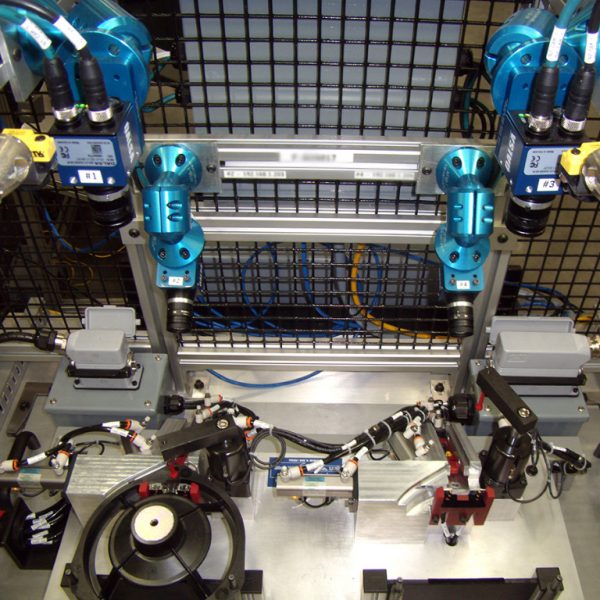

Modular Machines:

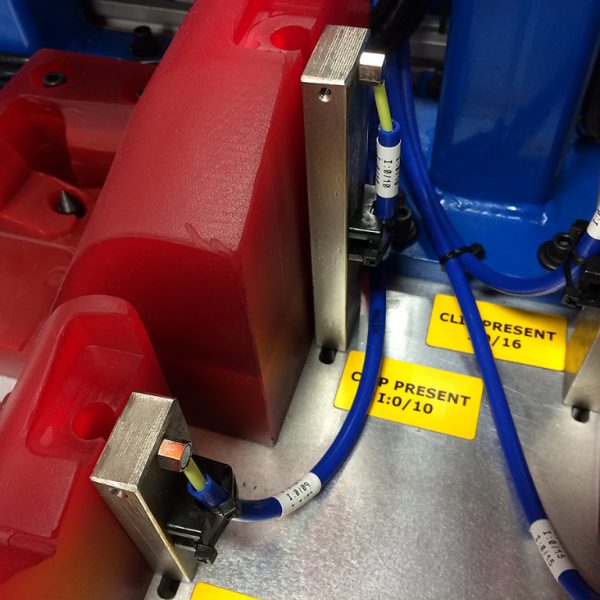

Blue Water Controls has saved its customer tens of thousands of dollars providing modular equipment solutions. These interchangeable nesting and tooling plates help save on capital equipment costs, storage space requirements, and change time labor. Our systems all have electrical and pneumatic quick change integration with automatic detection of nesting to modify and change PLC and HMI programs.

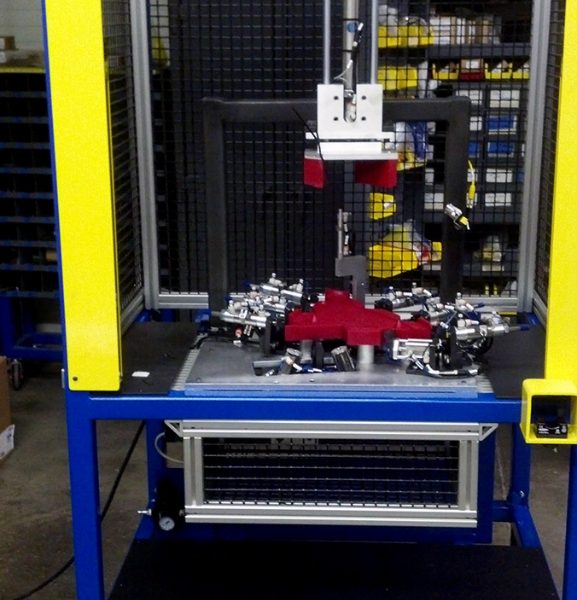

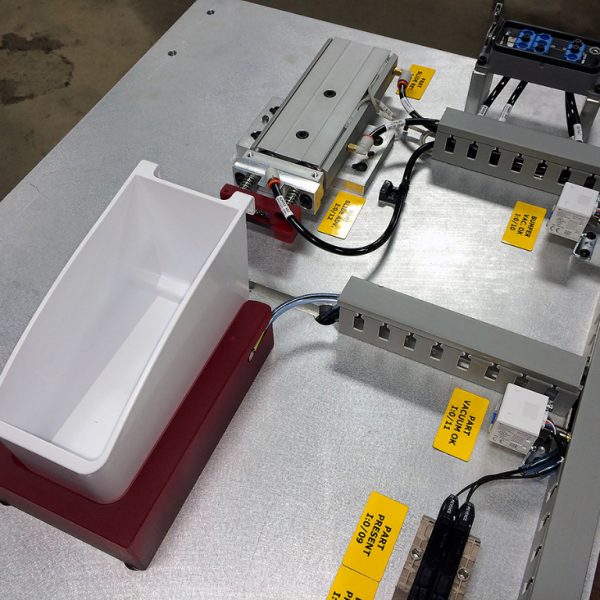

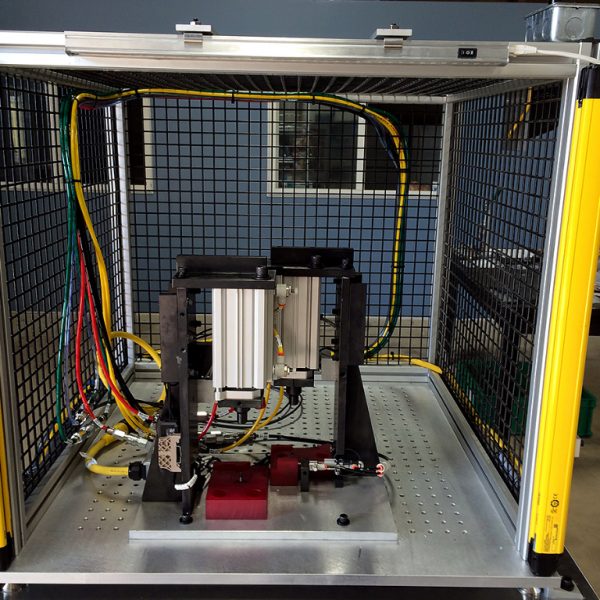

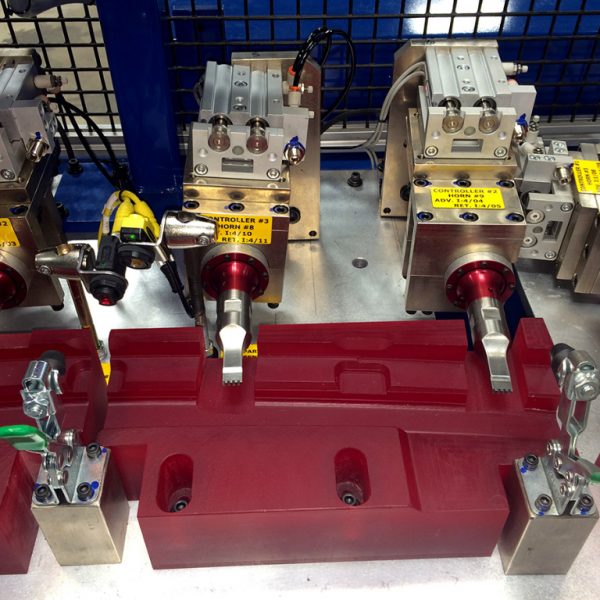

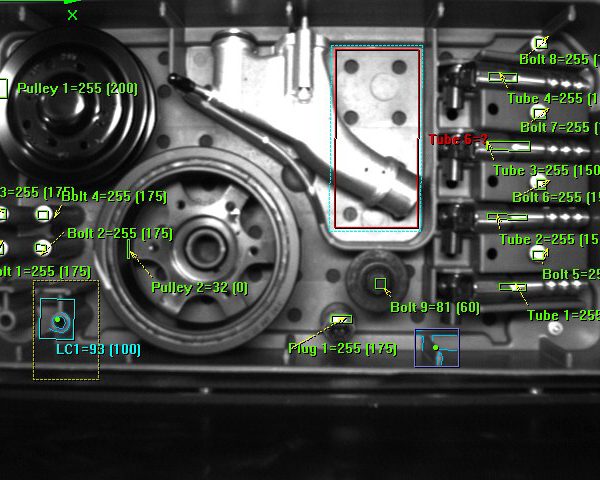

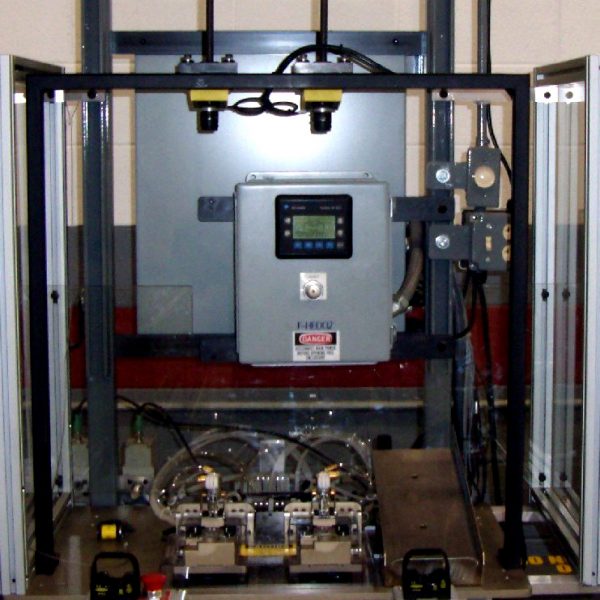

Verification Machines:

We take pride in developing robust solutions to verify all part content and cycle completion. Our design concepts take into consideration; ease in operator operation, part load / unload, and security part for a failed inspection of any type. We deploy sensors, vision systems and cycle monitoring to achieve this.